I am posting this in the ITB section because I know my build thread is not seen as much throughout the board. I hope this will be of some use for people trying to make N/A power without getting into expensive and risky bottom end work.

The head on my engine is not ported at all, just shaved .060". Supposed to be around 11.5:1 compression now, but I am not sure if it was actually raised that much. The key here is making this setup easily reproducible. If the block fails, I can go buy another stock block and be up and running quick. If I needed a new head, I can buy one and the only machine work needed would be a 135.00 shave. No rotating assembly work, no clearancing (other than cold lash), no balancing, no porting, etc.

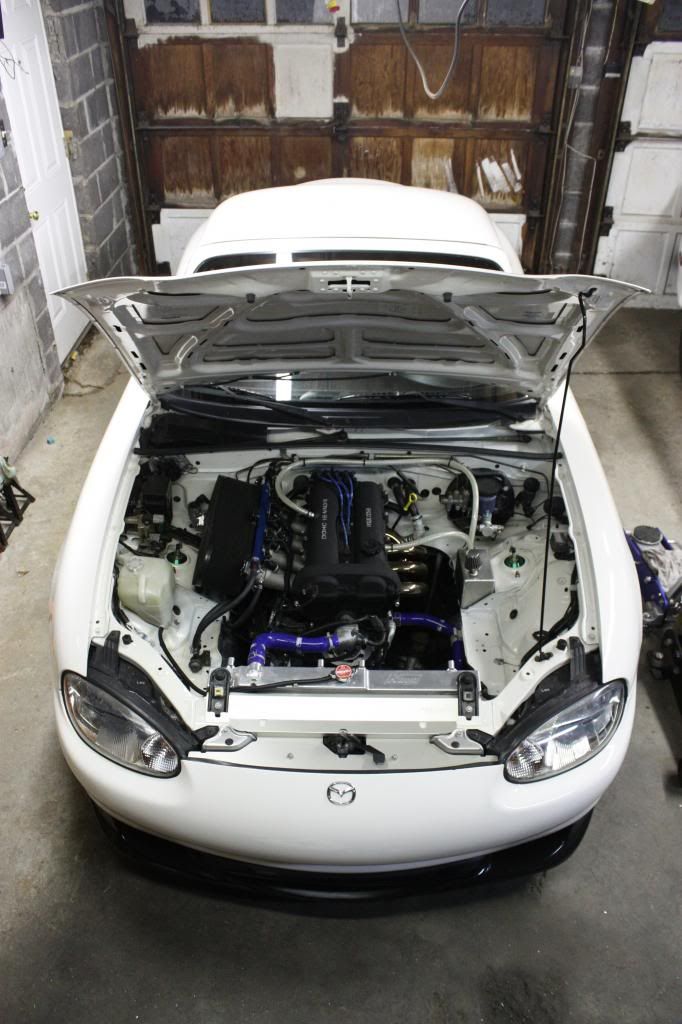

Engine:

2002 Block 10:1 compression

Cams are 264 / 264 10mm Lift Maruha's

Supertech Single Valve Springs

Supertech Titanium Retainers

Mazdaspeed SUBS

Toda Adjustable Cam Gears

New OEM Valve Seals

OEM Head Gasket

TWM 45mm Individual Throttle Bodies

36 lb Fuel Injectors

ITG Sausage filter and backing plate

Hondata Intake Manifold Gasket

Adaptronics Standalone ECU

Maruha VP Race Header

Racing Beat Resonated Race Pipe 2.375"

Jet's Integral Kobe Muffler 2.375"

Garage Star Alternator and Waterpump Pulleys

6.2 lb Spec Billet Pressure Plate

7.1 lb Fidanza Flywheel

1.3 lb Clutchnet Unsprung Street Disk

Golden Eagle Vacuum Manifold

Chikara Motorsports Oil Catch Can

Koyo 52mm Radiator

Koyo 1.3 Bar Radiator Cap

Mishimoto Slim Fan

Samco Radiator Hoses

Flyin Miata Oil Cooler Kit

Beatrush Radiator Cooling Panel

This stock 02 block at 10:1 compression, tested at 200-205 psi in each cylinder with the stock cams in previously. With the new cams creating more overlap and the head shave at .060" supposedly 11.5:1 compression, it tests at 205-210 psi in each cylinder. So with stock cams in the head creating less overlap it would most likely test much higher compression on the gauge. Honda's F20c at 11:1 compression on the non-VTEC lobes compression tests around 230-240 psi depending on the gauge.

With a .060" shave and 10:1 factory pistons, there is still a good 1-1.5mm of clearance in the reliefs. My friend/tuner was telling me to shave .080", but I was scared because the highest I was told I can go was .030", and I asked a lot of the big name Miata guys this too. I should have done .080". If the head ever comes off, I am going to shave it again to .080".

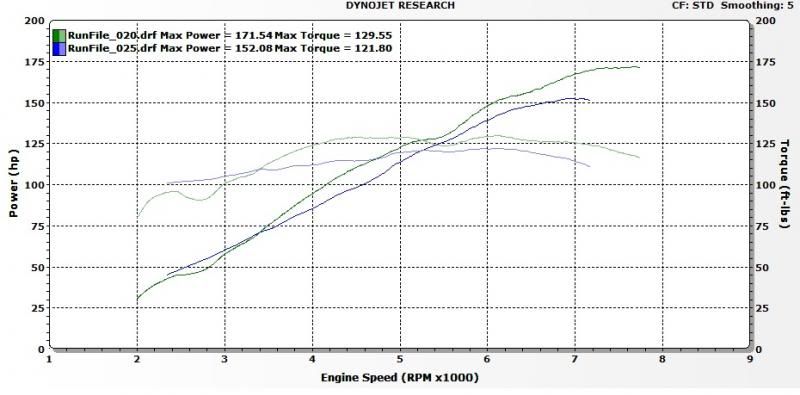

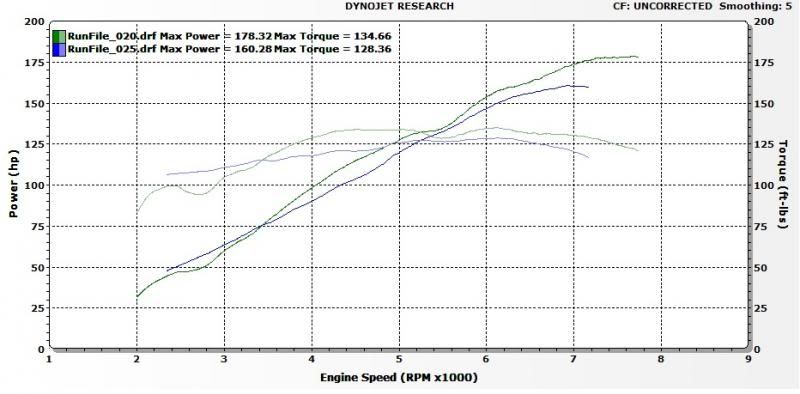

The results of all of this? Here are before and after comparisons of both the corrected dyno numbers and the uncorrected (what car was actually making at that very point in time). We fiddled with the cam gears on the street and on the dyno as well. These engines are not very sensitive to timing changes. Changing the cam and ignition timing yielded very little results. We advanced and retarded both the intake and exhaust cam quite a bit, but nothing significant changed. When we originally baselined the car it made 168 whp and 124 ft/lb's. We were however able to pick up a good chunk of mid-range power and settled with both the intake cam advanced about 6-7 degrees and the exhaust cam advanced about 3-4 degrees. We spent some time trying to get that funky dip out at 2600 rpm, but were only able to flatten it a little. We think it is just the nature of the cams and maybe the combination of them, the ITB's, and the header as well.

So there you have it. The idea behind this build was to avoid getting into costly bottom end work or head work and making the setup easily reproducible. Literally the only machine work required if the motor were to fail worst case would be shaving another head for 135.00.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

The head on my engine is not ported at all, just shaved .060". Supposed to be around 11.5:1 compression now, but I am not sure if it was actually raised that much. The key here is making this setup easily reproducible. If the block fails, I can go buy another stock block and be up and running quick. If I needed a new head, I can buy one and the only machine work needed would be a 135.00 shave. No rotating assembly work, no clearancing (other than cold lash), no balancing, no porting, etc.

Engine:

2002 Block 10:1 compression

Cams are 264 / 264 10mm Lift Maruha's

Supertech Single Valve Springs

Supertech Titanium Retainers

Mazdaspeed SUBS

Toda Adjustable Cam Gears

New OEM Valve Seals

OEM Head Gasket

TWM 45mm Individual Throttle Bodies

36 lb Fuel Injectors

ITG Sausage filter and backing plate

Hondata Intake Manifold Gasket

Adaptronics Standalone ECU

Maruha VP Race Header

Racing Beat Resonated Race Pipe 2.375"

Jet's Integral Kobe Muffler 2.375"

Garage Star Alternator and Waterpump Pulleys

6.2 lb Spec Billet Pressure Plate

7.1 lb Fidanza Flywheel

1.3 lb Clutchnet Unsprung Street Disk

Golden Eagle Vacuum Manifold

Chikara Motorsports Oil Catch Can

Koyo 52mm Radiator

Koyo 1.3 Bar Radiator Cap

Mishimoto Slim Fan

Samco Radiator Hoses

Flyin Miata Oil Cooler Kit

Beatrush Radiator Cooling Panel

This stock 02 block at 10:1 compression, tested at 200-205 psi in each cylinder with the stock cams in previously. With the new cams creating more overlap and the head shave at .060" supposedly 11.5:1 compression, it tests at 205-210 psi in each cylinder. So with stock cams in the head creating less overlap it would most likely test much higher compression on the gauge. Honda's F20c at 11:1 compression on the non-VTEC lobes compression tests around 230-240 psi depending on the gauge.

With a .060" shave and 10:1 factory pistons, there is still a good 1-1.5mm of clearance in the reliefs. My friend/tuner was telling me to shave .080", but I was scared because the highest I was told I can go was .030", and I asked a lot of the big name Miata guys this too. I should have done .080". If the head ever comes off, I am going to shave it again to .080".

The results of all of this? Here are before and after comparisons of both the corrected dyno numbers and the uncorrected (what car was actually making at that very point in time). We fiddled with the cam gears on the street and on the dyno as well. These engines are not very sensitive to timing changes. Changing the cam and ignition timing yielded very little results. We advanced and retarded both the intake and exhaust cam quite a bit, but nothing significant changed. When we originally baselined the car it made 168 whp and 124 ft/lb's. We were however able to pick up a good chunk of mid-range power and settled with both the intake cam advanced about 6-7 degrees and the exhaust cam advanced about 3-4 degrees. We spent some time trying to get that funky dip out at 2600 rpm, but were only able to flatten it a little. We think it is just the nature of the cams and maybe the combination of them, the ITB's, and the header as well.

So there you have it. The idea behind this build was to avoid getting into costly bottom end work or head work and making the setup easily reproducible. Literally the only machine work required if the motor were to fail worst case would be shaving another head for 135.00.